Electroplating is basically the process of plating a metal onto the other by hydrolysis mostly to prevent corrosion of metal or for decorative purposes. The process uses an electric current to reduce dissolved metal cations to develop a lean coherent metal coating on the electrode. Electroplating is often applied in the electrical oxidation of anions on a solid substrate like the formation of silver chloride on silver wire to form silver chloride electrodes.

Electroplating is majorly applied to modify the surface features of an object (e.g corrosion protection, lubricity, abrasion), but the process can also be used to build thickness or make objects by electro forming.

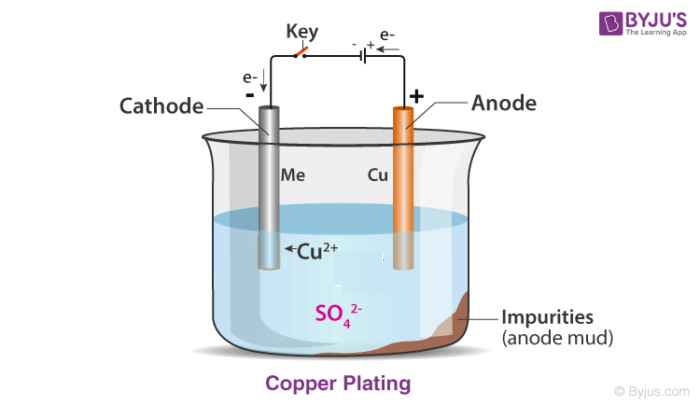

In electroplating practice, the current is usually introduced from an external source and the anode is the positive electrode and cathode is a negative electrode. The cathode is the electrode where the electrochemical reduction reaction occurs. The anode is that where the electrochemical oxidation reaction occurs.

The electroplating process uses an anode and a cathode. In electroplating, the metal dissolved from the anode can be plated onto the cathode. The anode is provided with direct current, oxidizing and dissolving its metal atoms in the electrolyte solution. At the cathode, the dissolved metal ions are decreased and the metal is placed on the product.

To understand the concept further, let’s take an example of a gold coating. In this instance, a layer of gold is to be electrodeposited on metallic jewellery to enhance its appearance.

Usually, the gold plating is connected to the anode (+ve charged electrode) of the circuit and the jewellery is kept at the cathode (-ve charged electrode). Both are kept immersed in a highly developed electrolytic bat (solution). At this stage, a DC current is supplied to the anode that oxidizes the gold atoms and dissolves them into the solution.

The dissolved ions of gold are reduced at the cathode and plated on the jewellery.

However, there are major factors that influence the last plating. These include:

· The voltage level of current.

· The temperature and chemical composition of the bath.

· The current length of time.

· The distance between the cathode and the anode.

Talking about the uses of electroplating, apart from enhancing the appearance of the substrate it is used in various other purposes as well. The major application is to optimize a material’s resistance towards corrosion. The plated layer often serves as a sacrificial coating which reveals that it dissolves before the base substance. Some of the other common applications of electroplating involve:

· Improving wear resistance.

· Improving the thickness of the metal surface.

· Enhancing the electrical conductivity like plating a copper layer on an electrical component.

· Minimizing Friction.

· Improving surface uniformity.

Source: www.byjus.com